Copyright 2011. figNoggle Designs.

7x10, 7x12, 7x14 Mini-Lathe Information

Website Links

Post a link to your website or view other hobby and machine and metalworking websites for free.

|

Rent Mill & Lathe DVDs at Smartflix | Great aluminum & steel prices at OnlineMetals Enco 20" 1PH Square Column Geared Head Mill Drill (aka Rong-Fu 45 Mill Clone) - Mill Stand Assembly After taking apart the RF45 clone for moving back to the shop, we then proceeded to assemble the stand where the mill would sit. We were hoping for a mill stand that came in one unit and was welded together. What we received was a flat box of sheet metal ready for assembly:

And the back of the box:

As you can kind of see from the parts list, the sides are pre-spot-welded into individual units with the front and back and internal sheet metal plates to be bolted to make one stand. The assembly was easy. We had read reports that the stand was pretty weak, but found this one to be pretty decent. Here's the label on the box:

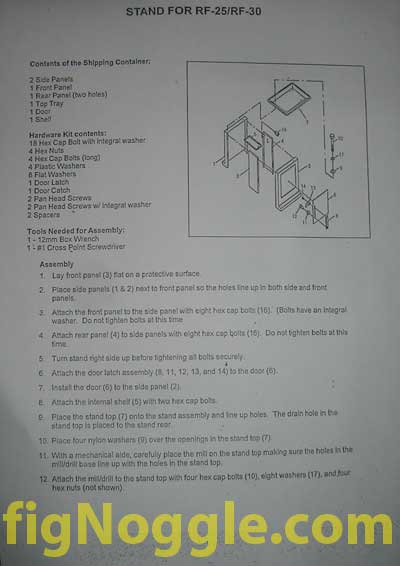

It's model #09519919. Note that it's made in Taiwan. This would imply better quality than had it been made in China. After opening up the box, we found the instruction sheet to yield some interesting clues as to the intended pairing of the mill with this stand:

Do you see what we see? It's for the RF-25/RF-30 mill/drills!? Well, since they're all basically the same, this should work out fine. We wanted to bring your attention to a close-up picture of the stand's welds on one of the legs:

This is intended to show the spot welds and give a sense of the guage of sheet metal used. Believe us, the legs are certainly strong enough to hold hundreds of pounds of weight. Once assembled, we put the drip tray on the stand and you now have the assembled mill/drill stand:

There's a little hole off to the upper right hand corner of the drip tray to collect fluids. The right hand side of the stand has a door which opens up to house a storage unit. Nothing fancy here. All in all, despite our expectations that this stand would be too weak to hold a 700# mill, we have to say that it does quite a decent job at it. Now that this is done, it's time to re-assemble the mill on the stand and take a closer inspection of its quality. |

Looking for mini-mill help and how-tos? How about lathe help and how-tos?

We're prototyping a benchtop CNC vertical mill using the DigiSpeed-XL interface card for Mach, Dart Controls and KB Electronics KBIC/KBMM 90VDC motor controllers, 1.5HP treadmill motor from Surplus Center and a R8-spindle head from the X2 mini-mill - not to mention Gecko servo drives and an entirely closed-loop system. Come take a look!CNC 8x12 Lathe

Check out our newest developments like the CNC/DRO 8x12/8x14 lathe using Gecko drives, break-out board, NEMA 34 step motors, DRO and more!

SUPERX3.COM

Sieg X3 and Super X3 Grizzly G0463 Info

MDAHacks.com

T-Mobile MDA / Cingular 8125 / HTC Wizard Hacks, Tweaks, Tips, Tricks and More!

Metal Working FAQ.NET

Your source for metalworking and machining, tips, tricks, and more. Over 50 content wiki sites!