Copyright 2011. figNoggle Designs.

7x10, 7x12, 7x14 Mini-Lathe Information

Website Links

Post a link to your website or view other hobby and machine and metalworking websites for free.

|

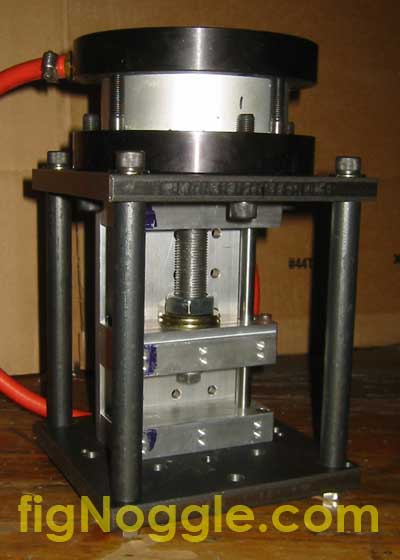

Rent Mill & Lathe DVDs at Smartflix | Great aluminum & steel prices at OnlineMetals STAMP AND CRIMP MACHINE This is the first prototype of the stamp/crimp machine built using the mini-mill. Simple design. Operable manually or by timer. No safety mechanism in place.

Here is version 2 of the crimping/stamping machine. We have designed it such that the tooling is modular. The machine still employs four legs/ties to keep the unit together. The internal subassembly is removable and resembles one axis of a linear table. It uses Thompson-brand linear rod with bronze-embedded collar "bearings" to provide additional linear support. The air cylinder this time is a 4" diameter with a 1" stroke, which should yield a theoretical (at 100 psi) pi*[(bore/2)^2] * 100 = 1256 lbs (just a little over 1/2 ton of force).

The 3/4"x16tpi threaded rod was done using the 8x12 minilathe. It's times like this when we wished that we had reverse, quick-change gear box, and speed selection capabilities. Turning at 120rpm and stopping short to finish by hand, then removing the belt to move the carriage back (we lost the little threading gear - so make sure you loctite it down!) gave us all Popeye forearms at the end of the project. Another version of the crimping machine is more substantial and essentially takes a hand-operated crimper and puts in into a frame that is powered by the same 4" dia. bore air cylinder. With the compound leverage, we get over 1 ton of force at 100psi. 40psi is enough to crimp electrical ring terminals and swaging components like those sold by Nicopress and Campbell. The entire unit is made of extruded 3/8" 6061-T6 aluminum and the lock pins that replaced the ones that held together by the stock pins are turned of mild steel again on the mini-lathe. The air cylinder acts as a structural element since it bolts down to the 1/2" thick mild steel plate (12" square). This is really much more of a crimping machine than even version 2 as shown above. We'll be adding more to this. Right now, it's simply connected to a airline and switch. Note the recess in front of the head. This keeps the crimping head out of the way.

|

Looking for mini-mill help and how-tos? How about lathe help and how-tos?

We're prototyping a benchtop CNC vertical mill using the DigiSpeed-XL interface card for Mach, Dart Controls and KB Electronics KBIC/KBMM 90VDC motor controllers, 1.5HP treadmill motor from Surplus Center and a R8-spindle head from the X2 mini-mill - not to mention Gecko servo drives and an entirely closed-loop system. Come take a look!CNC 8x12 Lathe

Check out our newest developments like the CNC/DRO 8x12/8x14 lathe using Gecko drives, break-out board, NEMA 34 step motors, DRO and more!

SUPERX3.COM

Sieg X3 and Super X3 Grizzly G0463 Info

MDAHacks.com

T-Mobile MDA / Cingular 8125 / HTC Wizard Hacks, Tweaks, Tips, Tricks and More!

Metal Working FAQ.NET

Your source for metalworking and machining, tips, tricks, and more. Over 50 content wiki sites!