OK, this post is off-topic ![]() Let us first show off some cool architecture:

Let us first show off some cool architecture:

In recent years, we have attended many metalworking and fabrication tradeshows including EMO, IMTS, Westec (Eastec, Southtec, etc..), Fabtech and have never seen a show (well, EMO was a close second) as large as the Canton Fair in Guangzhou, China. This may sound more like a travel blog than a metalworking website chock-full of information and insight (which reminds us that we have to get the old “Workshop” blog entries back online :), but this entry is necessary if we want to see the scale of what we as machinists, engineers, and product-making people do on a worldwide level.

OK, OK. Let’s not get into the discussion of offshoring, onshoring, re-shoring, Pauly Shore (OK, we’ll keep our day jobs ![]() Let’s just stand back and observe what we see happening.

Let’s just stand back and observe what we see happening.

Now, for us local state-side machinists and enthusiasts of machines that make parts, we have the regional tradeshows such as Westec, which is run every other year in Los Angeles, California at the LA Convention Center. Its largest booth in recent memory is Haas (remember now that Haas is a hugely successful marketing organization making affordable machines for those of us getting started – did you also know that they’ve come out with a 5-axis mill UMC-750?), with other machine makers following. There are many smaller vendors selling unique tools and solutions that are supposed to help our industry. With hundreds of exhibitors and lasting only three days, this regional show gives us a sense of the local supporters of manufacturing. Great!

On a national level, we have the IMTS show in Chicago, alternating with a worldwide show – EMO in Hannover, Germany. Imagine IMTS being all of the regional shows on steroids (i.e. larger booths and more marketing) consuming all of Chicago during the week-long event. At IMTS, we have all the major players in machinery building including but not limited to Haas, Mori-Seiki, Okuma, Mazak, Bridgeport and the countless China and Taiwan makers and their ecosystem of supporting vendors who make the brains and consumables that make these machines useful to you and me. With nearly two thousand exhibitors and over 100,000 buyers and sellers from over 119 countries, the show becomes overwhelming very quickly (wear comfortable shoes!). From this national show, we get a good sense of who’s supporting the manufacturing (from a metalworking perspective) industry. This is equally comparable in theory to the Fabtech show (think welding, grinding, forming sheet metal).

Marry those two shows (IMTS and Fabtech) and you now are getting close to the size of EMO, which, amazingly is ONLY truly for metalworking. Europe has another metal fabrication show (the name escapes me now with all of the acronyms flying about), and we’ll get to that one later… Once married, they beef up on steroids. THAT is EMO, occupying 1,900,000 square feet. HUGE!

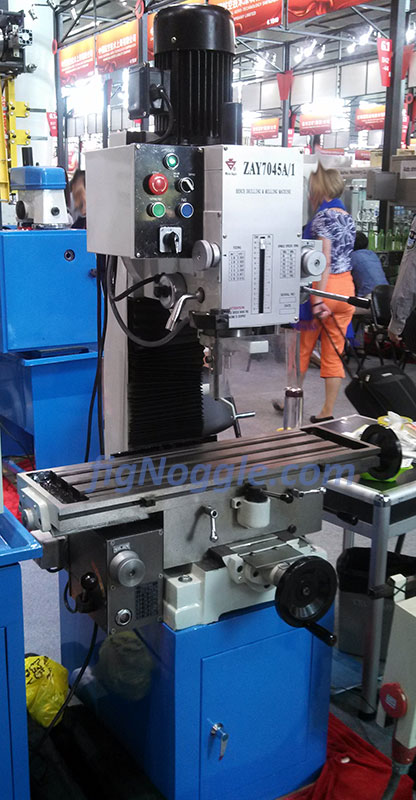

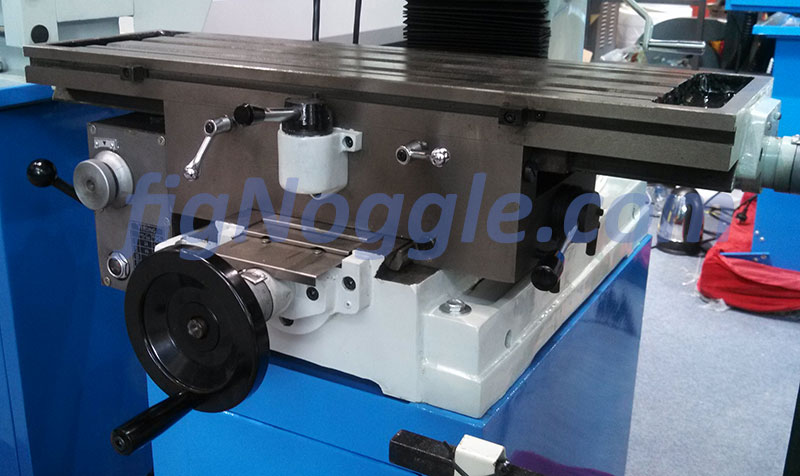

Fast forward to the train ride from Hong Kong to Guangzhou, where a bullet train from Shenzen to Guangzhou (both continually up and coming industrial cities) travels at 217 mph and gets you to the Canton Fair in less time than it takes to walk one building of the 12,100,000 square-foot exposition size. That’s right, folks, it’s 6 times larger than EMO! Now, to be fair, the Canton Fair (not in it’s 114th year this year and no pun intended) showcases China’s production capacity of all things. We saw everything from hand tools to building supplies to machinery (in reality, only a handful of metalworking companies exhibited and all were from China, including SIEG!). There are Mainland China metalworking tradeshows too and that’s another entry altogether and they also get as big as EMO.

The entire point of this entry is to get us to see the scale of tradeshows, not so much just the metalworking ones. It amazed us to “see” production capacity as reflected by the scale of a single tradeshow. Amazing.

Oh, did we mention that the Canton Fair is broken up into three phases? Do the math on that!