This is a test of a remote ie via mobile phone post with pictures of the disassembly and cleaning of a scroll Chuck. There are a few tips you’ll find useful!

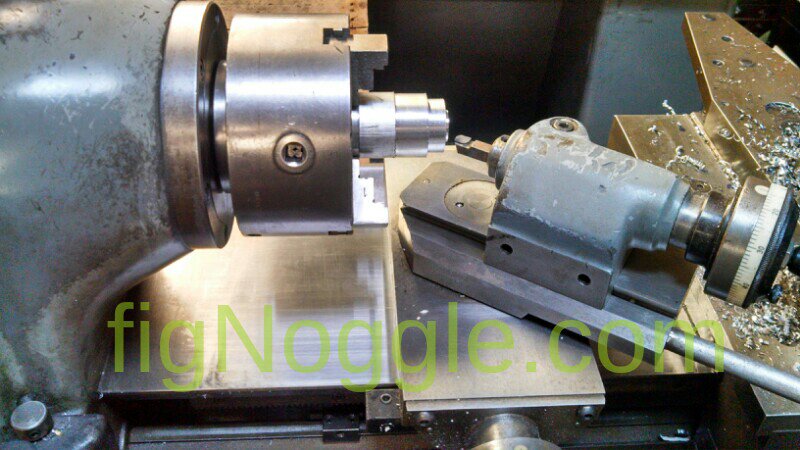

This is the aftermath of chuck removal and taking apart if the 5″ 3-jaw scroll chuck.

The first thing to do is to remove the jaws but before that you may want to mark the jaws to the chuck either by stamping or writing it down with a sharpie marker. Dykem markets are pretty nice too since they’re paint markers.

Once the jaws are removed just undo the socket head cap screws a wee bit and then place the chuck face down and tap the top of the bolts until the chuck body and mounting plate become slightly separated.

Now you can operate!

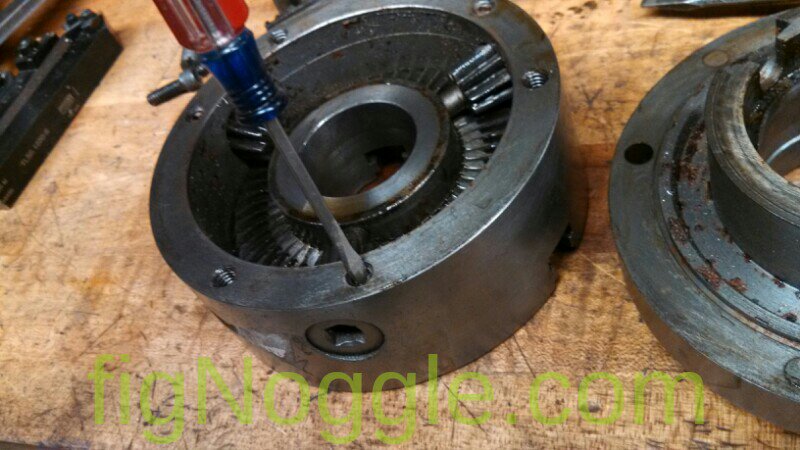

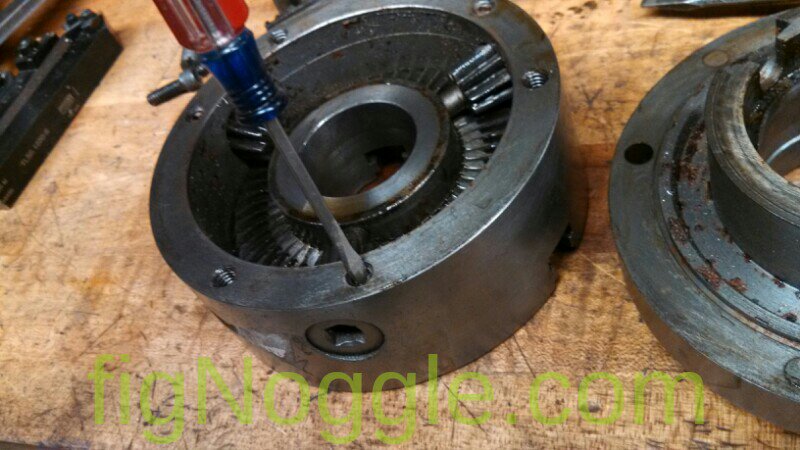

You may have to use a screwdriver prying it apart but do it gently!. Oh yes and you may also want to make witness marks registering the two halves before you separate them.

Once the halves are separated you can begin work on removing the opinion gears. Each gear has a capture pin. Just unscrew them out.

At this point if you’re lucky enough the gears will just slide out. If not you may have to drive them out. We use a brass pin since the gears are not hardened.

That was easy! Removing the scroll itself may be more difficult. Cross your fingers!

With the chuck body face up, use your brass pin to slowly drive it out. It’s a close fit and you may want to lube up the scroll and body before proceeding. Drive out the scroll if you can’t push out but do this carefully and gently!

That’s all there is to it!. Clean it all up and be sure to grease or oil.

![]()

![]()